Venture Machine & Tool designs and builds all tooling in-house with our highly qualified Tooling Engineers and our state-of-the-art equipment. Our process employs several quality controls to ensure the end product meets tolerances and is produced in an efficient and high quality manner.

Stamping

- VMT’s certified processes and quality controls ensure high quality and efficiency

- Material sourcing and vendor relationships ensure access to raw materials in a timely manner

- Sensor automation or in die measurements

- Nine coil presses ranging from 100 to 1,000 tons enable VMT to produce a variety of parts and volume levels efficiently

Capacity to handle larger, more complex, multi-step, and higher volume jobs

- Flexibility to efficiently manage the smaller, straight forward and low volume jobs

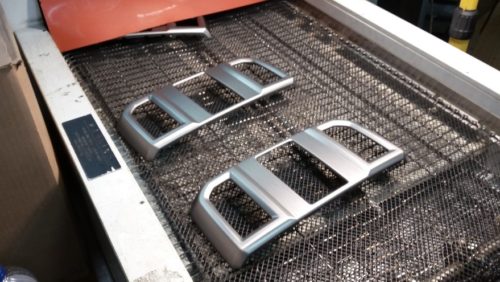

Decorative aluminum parts being washed and dried

1000 Ton Auto Transfer Press

Venture is expanding our transfer line to our 1000 Ton Verson press which will increase capacity to 256″ long

.

Value Added Operations

- Assembly of weld nuts or crimp nuts.

- Robotic Weldling or Manual Welding

- Heat treating internally or outside services

- Powder Coating or E-Coat as outside service

- Plating as outside services

- Deburring with Vibratory or Manual

- Tapping in die and post process

- Part testing to customer specifications

- Bar coding

Markets Served

- Automotive

- Seating

- Decorative Interiors

- Heat Shields

- Agricultural

- Appliance

- Lawn and Garden Equipment

- Heavy Construction Equipment

- Filtration/Exhaust

- Electrical Enclosures/Contacts

- Heat Exchanger, Petrochemical, Aerospace, Energy

- Recreational Vehicle

Stamping Equipment List

|

Coil Line Presses

|

Bolster

|

Shut Height

|

Window

|

Feed

|

Coil System

|

| 1000 ton Verson | 54″ x 256″ rolling | 30 1/2″ | 54″ | 30,000# | |

| 1000 ton Danly/Linear | 72″ x 120″, w/3 axis CNC transfer system | 36 1/2″ | 48″ |

30,000# |

|

| 800 ton Danly | 54″ x 108″ rolling | 25″-35″ | 42″ | 50″ Servo |

30,000# |

| 800 ton Danly | 54″ x 108″ rolling | 25″-35″ | 42″ | 48″ Servo |

30,000# |

| 600 ton Warco | 72″ x 84″ | 26″-38″ | 41″ | 40″ Servo | |

| 300 ton Verson | 54″ x 96″ | 20 1/2″-26″ | 28″ | 30″ Servo | |

| 250 ton Clearing | 54″ x 84″ | 28″-40″ | 26″ | 40″ Servo | |

| 200 ton Clearing | 48″ x 84″ | 17″-27″ | 18″ | 18″ Servo | |

| 100 ton USI | 36″ x 60″ | 14″-8″ | 16″ | 8,000# | |

| Secondary Presses | Bolster | Shut Height | Window | ||

| 1000 ton Verson | 54″ x 256″ rolling | 30 1/2″ | 54″ | ||

| 400 ton Minster | 72″ x 96″ | 23″-39″ | 20″ | ||

| 500 ton Clearing | 72″ x -120″ | 48″ | |||

| 500 ton Minster | 48″ x 84″ | 36″ | |||

| 400 ton Minster | 72″ x 96″ | 23 1/2″-39 1/2″ | 20″ | ||

| 300 ton Wean United | 72″ x 102″ | 26″-38″ | 46″ | ||

| 250 ton Verson | 52″ x 84″ | 17″-25″ | |||

| 4 – 150 ton OBI Danly | 30″ x 50″ | 16″-21″ | |||

| 150 ton Cleveland | 33″ x 55″ | 10″-16″ | |||

| 150 ton Danly | 30″ x 50″ | 17″-22″ | |||

| 105 ton Verson | 30″ x 39″ | 19″-23″ | |||

| 100 ton Bliss | 31″ x 34″ | toggle press | |||

| Other Value Added Equipment | |||||

| Power Point | Press Frame Welder | 30 amp Pneumatic | |||

| Cincinnati | Gauge Shear | 10′ x .150″ thick | |||

| Roesler | 9 cu. Ft. Vibratory Deburring System | ||||

| Technical Devices | Washer Dryer | 24″ wide Parts Conveyor | |||

| Performa | Hand Operated Plasma Cutters | ||||

| Welders | Mig/Tig Welders | ||||

| Uesco | Cranes |

Capacity up to 30,000 lbs. |

|||

| Hyster/Mitsubishi | Forklifts | Capacity up to 20,000 lbs. | |||